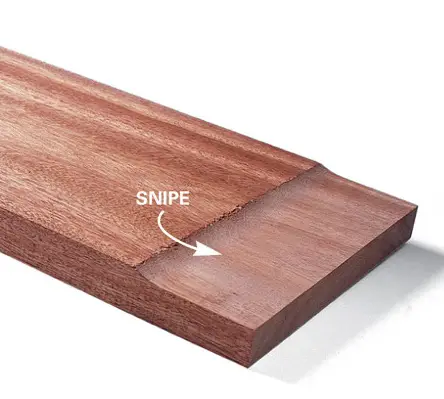

A snipe in woodworking refers to a groove or cut that is unintentionally made at the end of a wood piece. Snipes are often caused by the movement of the wood when it exits a planer or jointer.

These cuts can be undesirable as they can affect the overall appearance and functionality of the wood piece and may require extra work to fix. However, there are techniques that woodworkers can employ to minimize or eliminate snipes, such as using sacrificial boards or adjusting the machine settings.

By following these precautions, woodworkers can achieve clean, smooth cuts without any sniping.

Credit: www.finewoodworking.com

Understanding The Snipe Phenomenon

Snipe in woodworking refers to the frustrating occurrence of uneven cuts or gouges at the beginning and end of a planned board. This phenomenon can be caused by various factors such as inconsistent pressure on the workpiece or improper adjustment of the planer’s infeed and outfeed tables.

Snipe occurs when the planer blades dip slightly into the wood, resulting in unwanted imperfections. This can have a detrimental impact on woodworking projects, as it ruins the smoothness and uniformity of the finished piece. To minimize snipe, it is essential to ensure that the workpiece is properly supported throughout the planning process and that the planer is correctly set up.

By understanding and addressing the causes of snipe, woodworkers can achieve cleaner and more professional results in their projects.

Factors Affecting Snipe In Woodworking

Snipe in woodworking refers to the unwanted, partial depth cuts that can occur at the end of a workpiece when planning or jointing. Several factors can contribute to snipe, especially those related to the machine used in woodworking. These factors include the placement and adjustment of the infeed and outfeed tables, the condition of the blades or cutters, and the overall stability of the machine during operation.

Additionally, material-related factors can also increase the likelihood of sniping. These factors include the size and weight of the workpiece, as well as its orientation and grain direction. Wood species with irregular or interlocking grain patterns are more prone to snipe.

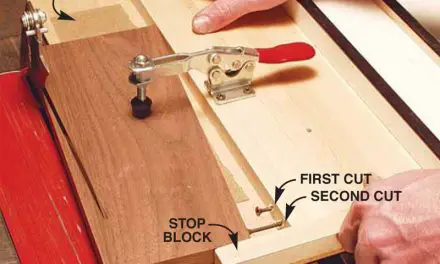

To minimize snipe, there are several techniques and tips that woodworkers can employ. These include using sacrificial boards at the beginning and end of the workpiece, making light passes, and ensuring consistent and even pressure throughout the cut. By implementing these strategies, woodworkers can reduce or even eliminate the occurrence of snipes in their woodworking projects.

Techniques To Reduce Or Eliminate Snipe

Snipe in woodworking refers to the frustrating phenomenon of uneven cuts or indentations at the ends of boards. To reduce or eliminate snipes, it’s important to properly set up and adjust planers and jointers. One technique is to make small adjustments to the infeed or outfeed tables to minimize the blade engagement.

It’s also helpful to use innovative accessories like snipe locks or infeed/outfeed supports to prevent snipes. Another important factor is understanding how different wood types behave. So, it’s best to adjust the planer or joiner accordingly. Follow best practices such as feeding the boards evenly and supporting them during the process.

By implementing these techniques and accessories, you can significantly minimize snipe, resulting in cleaner, smoother woodworking projects.

Evaluating And Finishing Woodworking Projects With Snipe

Snipe in woodworking refers to the slight dips or cuts that occur at the beginning or end of a board when running it through a planer or jointer. These imperfections can be frustrating for woodworkers, as they can mar the finished project.

To evaluate and finish woodworking projects with snipe, it is important to first identify and assess the snipe in the finished projects. Look for any noticeable dips or cuts at the ends of the boards. Once identified, techniques for sanding and smoothing sniped areas can be employed.

This may involve using sandpaper or a hand plane to carefully level out the sniped sections. Finally, applying the final touches and finishes such as varnish or polyurethane can enhance the appearance of sniped sections, making them blend in seamlessly with the rest of the project.

By following these steps, woodworkers can effectively address and minimize the impact of snipe in their finished projects.

Frequently Asked Questions For What Is Snipe In Woodworking?

How Do I Get Rid Of Snipe?

To get rid of snipe, ensure your wood is leveled and planed properly. Check the cutting knives for sharpness and adjust them as needed. Feed the boards into the planer with steady and even pressure. Avoid taking off too much material at once to minimize snipe.

For longer boards, support the ends to prevent them from drooping as they go through the planer. Gradually remove material by making multiple passes, adjusting the depth of the cut slightly each time. Lastly, inspect your wood after planning to check if any snipe remains.

If needed, lightly sand the snipe away. Regular maintenance and careful operation of your planer will help eliminate snipes and ensure smooth, professional-looking results.

What Is Snipe When Using A Planer?

Snipe in planning refers to a common issue where the planer blade cuts deeper at the beginning or end of a board, leaving a noticeable groove. It happens when the wood is not supported correctly. To avoid snipe, ensure the board is evenly supported throughout its entire length as it enters and exits the planer.

You can do this by using support tables or additional rollers at the infeed and outfeed sides of the planer. Properly adjusting the height of the planer blades and reducing the depth of cut can also alleviate snipe. It’s important to note that sniping is a common problem that can affect the quality of your woodworking projects, but with proper techniques and adjustments, it can be minimized or eliminated.

Why Does Snipe Happen?

Snipe, also known as bid sniping, occurs because of the nature of online auctions. Bidders wait until the last possible moment to place their bid in order to avoid driving up the price early on. By sniping, bidders hope to secure the item at a lower cost.

Additionally, sniping prevents other bidders from having a chance to counter with a higher bid. The fast-paced nature of online auctions, where time is limited, encourages sniping as a strategic move. Snipe tools and automatic bidding systems have made this practice even more convenient.

However, it is important to note that some auction platforms have implemented anti-sniping measures to level the playing field and discourage this behavior. Overall, sniping is a tactic employed in online auctions to increase the chances of winning an item at a lower price.

What Causes Snipe On A Jointer?

Snipe on a jointer is caused by an imbalance in pressure. When the wood passes through the jointer, it is subjected to uneven pressure, resulting in a snipe. This can happen due to a variety of factors, including improper technique or incorrect setup of the jointer.

It can also be caused by worn or dull blades, which do not cut evenly. To avoid snipe, it is important to feed the wood evenly and consistently, ensuring that both ends are supported as it goes through the jointer.

Additionally, using sharp and properly aligned blades will help minimize snipe. Regular maintenance and adjustments to the jointer can also help reduce snipe.

What Is A Snipe In Woodworking?

A snipe in woodworking refers to an indentation or mark that appears at the end of a board after it passes through a planer or jointer.

Conclusion

Understanding what a snipe is in woodworking is essential for any craftsman or hobbyist. This small, unintended dip in the wood can be frustrating, but it can also be fixed with the right techniques. By properly adjusting the settings on your planer and ensuring a smooth, consistent feed, you can reduce the occurrence of snipes.

Additionally, using sacrificial boards and making light cuts can help minimize the impact of snipe on your workpiece. Remember, proper planning and preparation are key to achieving professional-looking results in woodworking projects. So, don’t let snipe discourage you from pursuing your passion for woodworking.

With practice and patience, you can overcome this challenge and create beautiful, flawless pieces. Happy woodworking!