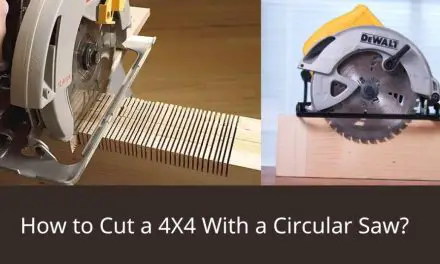

You can use a circular saw as a table saw by attaching it to a stable work surface and adding a fence for accurate cuts. By following proper safety precautions, you can create a makeshift table saw for woodworking projects.

Transforming a circular saw into a table saw can be a convenient and cost-effective option for woodworking enthusiasts. While a table saw provides better stability and precision, a circular saw offers portability and versatility. By converting your circular saw into a table saw, you can enjoy the benefits of both tools.

This article will guide you on how to use a circular saw as a table saw, allowing you to make accurate and straight cuts for various woodworking projects. So, let’s explore the process and safety measures involved in this DIY transformation.

Materials Needed

To use a circular saw as a table saw, you will need a few materials. First, you’ll need a circular saw itself. Next, you’ll need sawhorses or a workbench to support the saw. You’ll also need a piece of plywood or MDF board to create a table surface.

A measuring tape will come in handy for precise measurements. Use clamps to secure the circular saw to the table surface. Don’t forget to wear safety goggles to protect your eyes and ear protection for noise reduction. Following these guidelines, you can safely and effectively use a circular saw as a table saw.

Step 1: Setting Up The Work Area

To use a circular saw as a table saw, you need to start by setting up the work area. Clear a space for your work area, ensuring there is enough space to maneuver the circular saw. Set up sawhorses or a workbench to provide a stable surface for your materials.

Once your work area is set up, you can proceed with using the circular saw as a table saw. Remember to follow all safety precautions and guidelines when using power tools. By properly setting up your work area, you can efficiently and safely use a circular saw as a table saw.

Step 2: Preparing The Circular Saw

To prepare the circular saw for use as a table saw, start by checking the saw blade for any damage. This is important to ensure safe and accurate cuts. Adjust the blade depth to the desired height, depending on the thickness of the material you’ll be cutting.

Next, install a rip fence or guide onto the circular saw. A rip fence helps in making straight cuts and ensures consistent results. If available, attach a dust collection system to keep your workspace clean and prevent dust from getting into the saw’s motor.

This will also improve visibility while cutting. By following these steps, you can effectively use a circular saw as a table saw for various woodworking projects.

Step 3: Securing The Plywood Or Mdf Board

To secure the plywood or MDF board for use with the circular saw turned table saw, follow these steps. Firstly, measure and mark the desired cut on the board. Then, clamp the board securely to the sawhorses or workbench. Make sure that the board is stable and won’t move during cutting.

This is essential for accurate and safe cuts. By securing the board properly, you can effectively use the circular saw as a table saw, expanding its functionality and versatility. Remember to always prioritize safety when working with power tools, and wear appropriate protective gear, such as safety goggles and gloves.

Step 4: Making The Cut

To use a circular saw as a table saw, follow these steps for making the cut. Position the circular saw at the edge of the board and start the saw, letting it reach full speed. Slowly push the saw forward to make the cut, maintaining a steady pace.

Do not force the saw, as this can result in an uneven cut or potential accidents. It’s important to follow these guidelines to ensure safety and accuracy when using a circular saw as a table saw. With proper technique and attention to detail, you can achieve precise cuts and efficiently complete your woodworking projects.

Remember to always prioritize safety and wear appropriate protective gear while operating power tools.

Credit: www.kregtool.com

Step 5: Safety Precautions

To ensure your safety while using a circular saw as a table saw, there are some important precautions to follow. First, always wear safety goggles to protect your eyes from sawdust. Additionally, use ear protection to reduce noise levels and prevent hearing damage.

It’s crucial to keep your fingers away from the saw blade at all times to avoid any accidents. Lastly, make sure to carefully follow the safety guidelines provided by the manufacturer. By taking these safety measures, you can confidently use a circular saw as a table saw without compromising your well-being.

Step 6: Finishing Touches

To finish off your DIY table saw project, follow these final steps for accuracy and smoothness. Check the cut to ensure it matches your desired measurements and is free from any imperfections. Sand down any rough edges if necessary, making sure the surface is smooth to the touch.

Afterward, remove any clamps that were used during the construction process. Finally, take the time to clean up your work area, removing any debris or sawdust that may have accumulated. By completing these finishing touches, you’ll have a functional and reliable table saw created from your circular saw.

Step 7: Maintenance And Storage

To properly maintain and store a circular saw used as a table saw, it is essential to clean the saw blade and remove any sawdust after each use. This helps to prevent buildup and maintain the cutting performance of the blade.

Additionally, it is important to keep the saw in a dry and secure place to protect it from moisture and potential damage. Regularly checking and replacing any worn-out parts is also crucial to ensure the saw operates safely and efficiently.

Following proper maintenance procedures, such as lubricating moving parts and keeping the saw clean, can help prolong the lifespan of the saw and ensure its optimal performance.

Frequently Asked Questions Of How To Use A Circular Saw As A Table Saw?

Can I Make My Circular Saw Into A Table Saw?

Yes, it is possible to convert your circular saw into a table saw.

Can I Use Circular Saw Instead Of Table Saw?

Yes, you can use a circular saw instead of a table saw.

What Should You Not Do With A Circular Saw?

To ensure safety and proper use, here are four things you should not do with a circular saw: 1. Do not operate the saw without wearing appropriate safety gear. 2. Avoid cutting materials that are unsupported or unstable, as it can lead to kickbacks.

3. Never force the saw through the material, as it can cause the blade to bind or kickback. 4. Do not forget to unplug the saw before changing the blade or performing any maintenance tasks.

How Do You Cut A Straight Line With A Circular Saw?

To cut a straight line with a circular saw: 1. Measure and mark your desired cut line on the material. 2. Place a straight edge or guide along the marked line. 3. Align the saw blade with the guide, ensuring it’s perpendicular to the material.

4. Hold the saw firmly and make a steady, controlled cut along the guide.

Conclusion

Using a circular saw as a table saw can be a cost-effective and space-saving alternative for DIY enthusiasts or those with limited workshop space. By utilizing a few basic modifications and safety precautions, you can transform your circular saw into a functional table saw.

Remember, accuracy and safety should always be prioritized when working with power tools. Make sure to secure your circular saw properly to a stable surface and attach a fence for precise cuts. Additionally, invest in quality blades suitable for table saw tasks to achieve clean and efficient cuts.

However, it’s important to note that a circular saw converted into a table saw might not offer the same level of power and precision as a dedicated table saw. Therefore, it’s essential to consider your specific project requirements and the limitations of your tool before undertaking any woodworking task.

Keep practicing, be cautious, and enjoy exploring the potential of your circular saw!