A rabbet in woodworking is a notch or groove cut into the edge of a board, with the two sides forming a 90-degree angle to each other. It is used for joining boards together or for creating a recess in a frame.

In woodworking, rabbets are commonly used in various joints such as dado, mortise and tenon, finger joint, and bridle joint. They differ from dados and grooves in that rabbets are cut on the edge of a board, while dados run across the grain and grooves run with the grain.

Understanding the concept of rabbets is essential for woodworking enthusiasts to create strong and seamless joints in their projects.

Understanding Rabbet Joints

A rabbet joint is a woodworking joint that involves cutting a notch along the edge of a piece of wood, typically at a right angle to create a groove. This joint is commonly used to join two pieces of wood together, creating a strong and secure connection.

The purpose of rabbet joints is to provide additional surface area for gluing, making the joint more stable and durable. Rabbet joints are commonly used in cabinet and furniture making, as well as in window and door construction. They are versatile and can be used for creating dadoes, grooves, and other types of joinery.

Understanding rabbet joints is essential for any woodworking enthusiast as they are a fundamental technique in the craft.

Types Of Rabbet Joints

A rabbet in woodworking refers to a notch or groove cut into the edge or face of a piece of wood. It is commonly used to create joints and connections between different pieces of wood. Under the heading of “Types of Rabbet Joints,” one of the subheadings is “Dado rabbet joints.

” Dado rabbet joints are created by combining a rabbet joint with a dado joint, resulting in a stronger and more secure connection. Another subheading is “Mortise and tenon rabbet joints. ” This type of joint combines the strength and stability of a mortise and tenon joint with the added reinforcement of a rabbet joint.

Finger joint rabbet joints are also mentioned, which involve connecting two pieces of wood using interlocking fingers. Lastly, there are bridle joint rabbet joints, which use a combination of a bridle joint and a rabbet joint for a secure and durable connection.

These various types of rabbet joints offer different strengths and benefits depending on the specific woodworking project at hand.

Tools And Techniques For Creating Rabbet Joints

A rabbet in woodworking refers to a notch or groove cut along the edge of a wooden board. This technique is commonly used to create joints in furniture making and carpentry. To create rabbet joints, various tools and techniques can be employed.

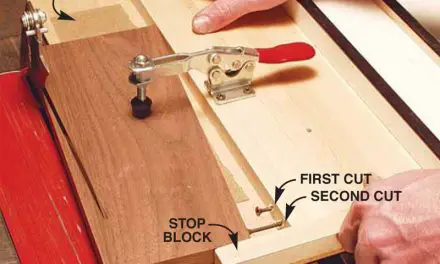

One popular method involves using a handheld router. This versatile tool allows for precise and controlled cutting along the edge of the board. Additionally, creating a router jig can help ensure consistent and accurate rabbet cuts. When using a handheld router, selecting the right router bit is crucial.

Different bits can be chosen depending on the desired size and depth of the rabbet. Lastly, setting the blade height on the router is important for achieving the desired depth of the cut. Overall, mastering rabbet joints requires practice and familiarity with woodworking tools and techniques.

Common Applications Of Rabbet Joints

A rabbet joint is commonly used in woodworking for various applications. One of its common applications is building drawers and cabinets. It allows for a seamless and sturdy connection between the different parts of the furniture. Additionally, rabbet joints are also used in constructing bookshelves and cabinets, providing structural integrity and stability.

Joining picture frames is another popular application of rabbet joints, ensuring that the frame components fit together securely. With its versatility and strength, rabbet joints are essential in woodworking projects that require durable and precise connections.

Advantages And Disadvantages Of Rabbet Joints

A rabbet joint in woodworking refers to a notch or groove cut along the edge of a board. It is used to join two pieces of wood together, creating a strong and stable connection. One advantage of rabbet joints is their strength, as the overlapping of the boards provides increased stability.

Additionally, rabbet joints are relatively easy to create and require minimal tools. However, there are some limitations and considerations to keep in mind. For example, rabbet joints may weaken the overall structure of the wood, especially if the joint is too deep or wide.

It is important to carefully plan and measure the dimensions of the rabbet joint to ensure a proper fit. Additionally, rabbet joints may not be suitable for certain types of projects or materials. Overall, understanding the advantages and disadvantages of rabbet joints can help woodworkers make informed decisions when joining pieces of wood together.

Credit: www.amazon.com

Tips And Tricks For Mastering Rabbet Joints

A rabbet in woodworking is a notch or groove cut along the edge of a board. It is typically used to create joints in woodworking projects. When mastering rabbet joints, proper measurement and layout techniques are crucial. Accurate measurements ensure that the rabbets fit together seamlessly for a sturdy joint.

Securing and aligning the joints is another important aspect of mastering rabbet joints. Clamps or other methods can be used to hold the pieces together while the joint is being assembled. Lastly, finishing and sealing the rabbet joints is essential for longevity and aesthetics.

This can involve sanding the joints smooth and applying a suitable finish or sealant to protect the wood. By following these tips and tricks, you can achieve professional-looking rabbet joints in your woodworking projects.

Frequently Asked Questions For What Is A Rabbet In Woodworking?

What Is The Difference Between A Dado And A Rabbet?

A rabbet is a notch cut on the edge of a board, while a dado is a slot that runs across the grain.

What Is The Difference Between A Rabbet And A Rebate?

A rabbet and a rebate are essentially the same thing in woodworking. They both refer to a cut made on the edge of a board to create a recess or groove for joining purposes.

What Are 4 Different Types Of Rabbet Joints?

There are four different types of rabbet joints in woodworking: dado, mortise and tenon, finger joint, and bridle joint.

Conclusion

A rabbet is a fundamental woodworking joint that adds strength, stability, and functionality to various woodworking projects. Whether it’s joining two pieces of wood or creating a recessed edge for a door or window frame, understanding the concept of a rabbet is crucial for any woodworker.

By incorporating a rabbet joint, woodworkers can achieve a clean and seamless connection between wooden components, ensuring durability and longevity. This joint, with its simple yet effective design, allows for hassle-free assembly and enhances the overall structural integrity of the project.

Moreover, rabbets offer versatility, enabling woodworkers to create unique designs and incorporate decorative elements. With this joint, one can easily achieve a professional finish and elevate the aesthetic appeal of their woodworking projects. A rabbet is much more than just a simple woodworking term.

It is a versatile joint that plays a crucial role in enhancing the strength, functionality, and visual appeal of woodworking projects. By understanding and incorporating rabbet joints into their work, woodworkers can take their craft to new heights. So, embrace the world of rabbets and unlock endless possibilities in your woodworking endeavors.